Controlled by a handheld remote, robots perform operations without the need for manual high-altitude work or scaffolding.

The Hydroblasting Robot utilizes ultra-high-pressure water jet technology and is equipped with a wastewater recycling system, enabling efficient rust removal operations on ship hulls. It is suitable for various areas of ships such as the curved surfaces of the sides, large vertical planes, bottom surfaces, decks, or internal compartments.

Wallhiker

W-2025

Wheeled Wall-Crawler Robot

Wallhiker

EX-02

Explosion-Proof Wall Climbing Robot

Wallhiker

W-03

Flat Bottom Robot (Blast Cleaning Robot (Ship Bottom))

Wallhiker

H-01

Semi-Automatic Cleaning Robot

Wallhiker

H-02

Semi-Automatic Cleaning Robot

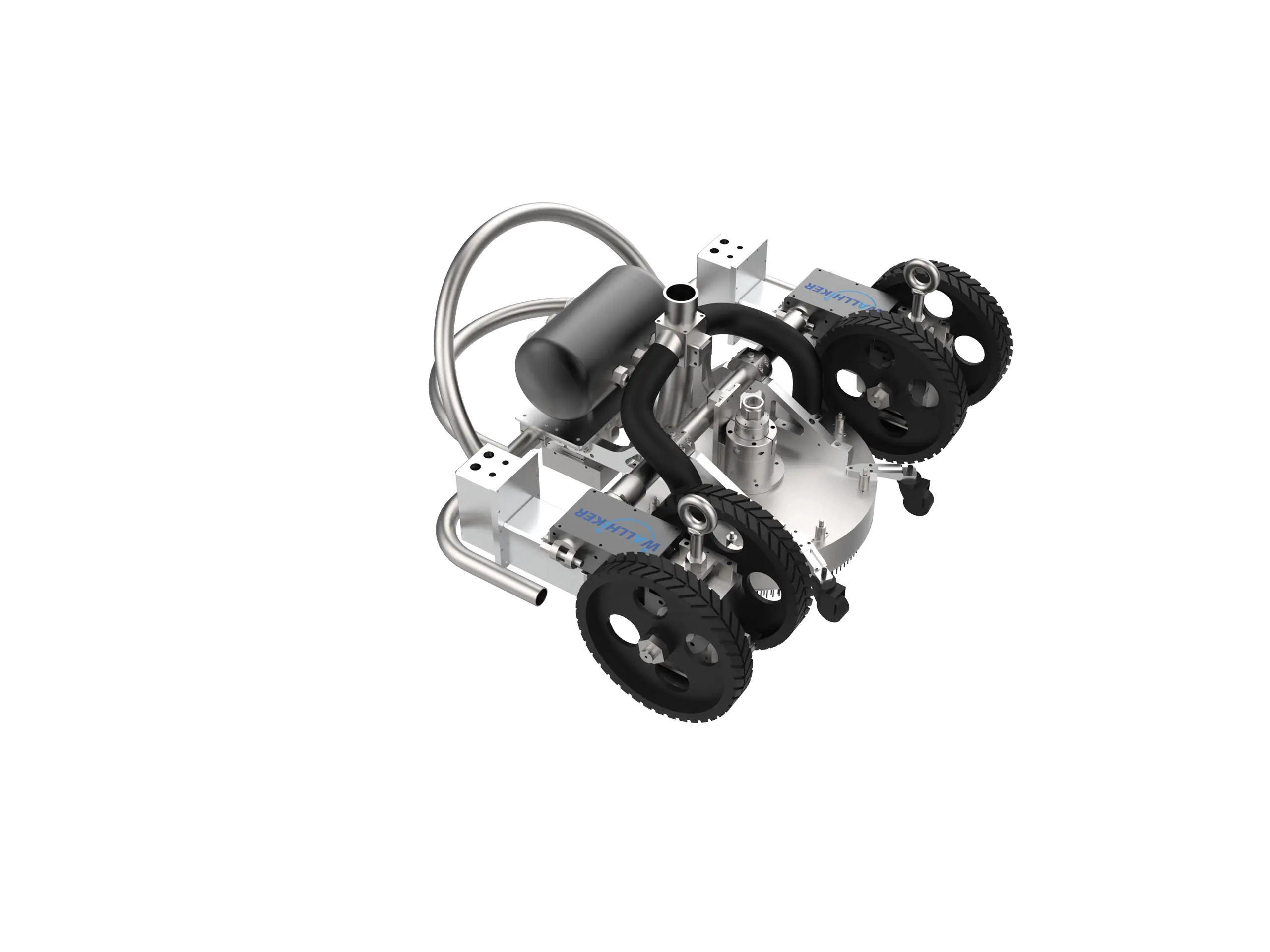

SR-01

Wastewater Recycle Robot

The ship hull rust removal robot designed by AKA Robotics utilizes a magnetic climbing robot as its carrier, equipped with an ultra-high-pressure water jet cleaning disc to achieve rapid rust removal and paint stripping. The waste water and residue generated during the rust removal and paint stripping process are processed using a vacuum recovery machine, achieving the goal of reducing emissions and promoting environmental protection through recycling.

Hydroblasting is a cleaning method that employs high-pressure water to eliminate dirt, rust, paint, scale, and other impurities from surfaces.

UHP (Ultra-High Pressure) Water Blasting is a type of hydroblasting that uses extremely high water pressure, usually greater than 1,700 bar (25,000 psi). UHP water blasting is extensively used in shipbuilding, oil and gas, and infrastructure maintenance to remove thick coatings, heavy rust, or scale.

Both water blasting and Sandblasting are two of the most common methods for coating removal and surface cleaning. Here's a comparison:

| Aspect | Water Blasting | Sandblasting |

| Medium Used | Uses high-pressure water. Abrasive materials like sand or garnet can be used for better performance, but water is primary. | Uses compressed air and sand (or other abrasives) to clean surfaces. |

| Environment and Safety | More environmentally friendly, uses water, no dangerous dust or particles. Vacuum suction tech collects and processes wastewater and paint debris. | Generates waste (abrasive materials, dust) that can harm workers and the environment. |

| Surface Impact | Causes less surface damage; impact is milder and adjustable to protect delicate textiles. | More abrasive, may cause wear or damage, especially on softer materials. Changes surface texture. |

| Cleaning Efficiency | Highly effective for rust, paint, grease, and other pollutants, without damaging substrate. Great for fragile surfaces. | More effective for tough coatings, corrosion, and debris removal, but harsher on sensitive materials. |

| Applications | Used in shipbuilding, pipeline cleaning, industrial equipment maintenance, paint/coating removal, and cutting soft materials. | Used in surface preparation for painting, coating, welding, and heavy-duty cleaning of metal, concrete, and stone. |

Controlled by a handheld remote, robots perform operations without the need for manual high-altitude work or scaffolding.

The vacuum suction system recovers and processes waste water and paint residue generated during rust removal. Water droplets evaporate rapidly from the surface after operation due to the ultra-high-pressure water jet nozzle's vacuum and high-temperature conditions, resulting in immediate drying, no re-rusting, and a rust removal grade of up to Sa2.5.

The uhp water blasting equipment is easy to operate, highly automated, and requires only 1 to 2 operators to control the robot to complete ship hull construction.